| Copper cables |

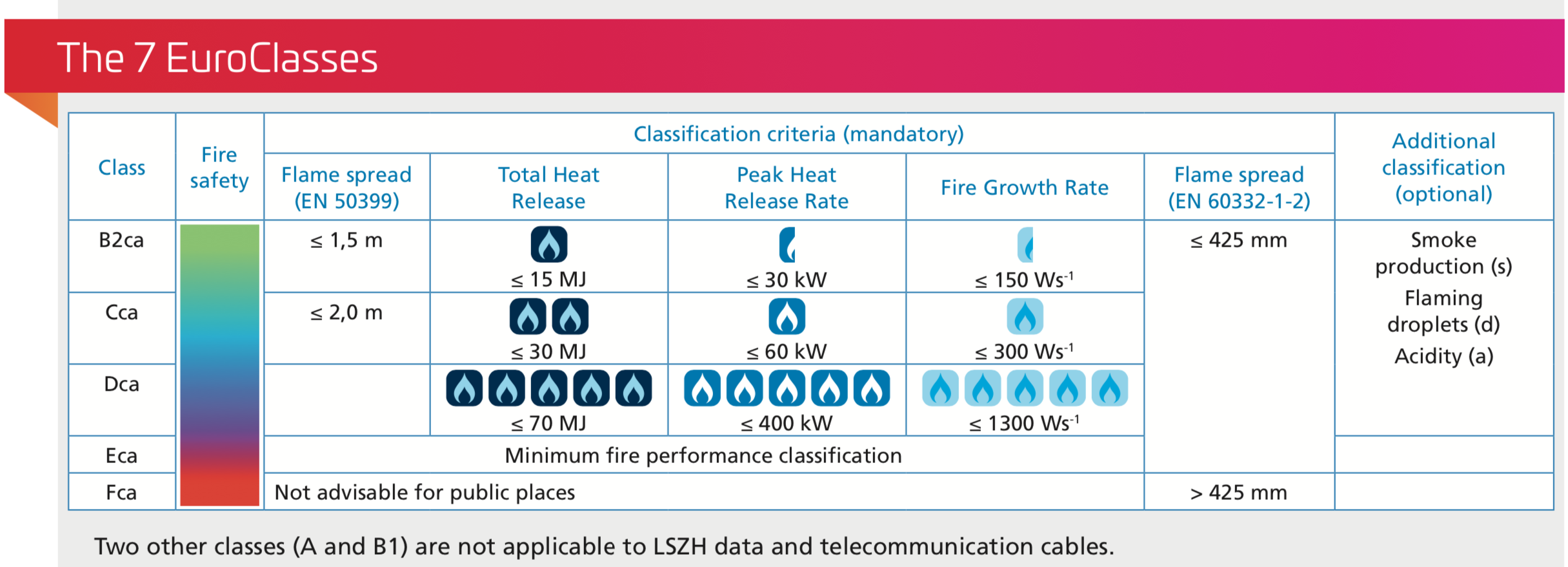

Dca |

Cca |

B2ca |

| Cat 7/7A |

|

|

|

| Cat 6A |

|

|

|

| Cat 6 |

|

|

DMR |

| Cat 5e |

|

DMR |

DMR |

| Fiber cables |

Dca |

Cca |

B2ca |

| Distribution Construction |

|

|

|

| Multi Loose tube construction |

|

|

|

| Single Loose tube/ drop construction |

|

DMR |

DMR |

| Hybrid/PFC cables |

|

|

DMR |

What is the difference between LSZH and OFNR?

With the many types of fiber cables and then the components that make each of them up, it can be very confusing to know what fiber cable is the best overall for your business. One of the biggest questions we get is what is the difference between OFNR fiber cables and LSZH fiber cables. While they seem like the same thing, they are really two very different and very important attributes of fiber cables, and the same fiber cable can be both. To understand these attributes better, we have to understand the construction of fiber cables and the different rating levels associated with fiber optic cabling.

Optical Fiber Construction

There are several parts that made up the fiber cable. Each part starting from the cladding, then the coating, strength member and lastly the outer jacket is covered at the top of each other to give protection and shielding especially the conductors and the fiber core. Above all of these, the outer jacket is the first layer of protection and adds strength to the fiber to withstand different conditions such as fire, moisture, chemical, and stress during installations and operations.

Fiber Cable Outer Jacket Material Types

Fiber cable outer jackets can be classified into several types in terms of different materials. These materials have different characteristics and use that depends on the application’s setting. The list below shows the most popular types of outer jacket materials and its uses.

materials and its uses.

| Material |

Characteristics and Uses |

| PVC (Polyvinylchloride) |

Most commonly used material for outer jacket. It is low cost, strong, flexible, fire resistant and can be used in many applications. |

| PE (Polyethylene) |

Very good electrical properties while maintaining high insulation. PE cables may be firm and solid but are more flexible. |

| PVDF (Polyvinyl Difluoride) |

Has more flame-resistant properties than the PE cable and primarily used for plenum areas. |

| PUR (Polyurethane) |

PUR is very flexible and scratch resistant that is mainly used in low-temperature environments. |

| TPR/TPE(Thermoplastic rubber/elastomer) |

Thermoplastic elastomers have excellent low-temperature properties without spending the money needed for a thermoset material. It has good chemical and oil resistance and is also quite flexible. Good abrasion resistance and surface texture, but is not as rugged as PUR. |

| Thermoplastic CPE(Chlorinated Polyethylene) |

Generally used in very harsh environments. It is lightweight, very rigid, and has a mildly rough surface texture and a low coefficient of friction. It is low-cost relative to the level of oil, moisture, chemical and UV resistance provided. |

| LSZH (Low Smoke Zero Halogen) |

LSZH is less toxic than PVC. It has a flame-retardant outer cover that doesn’t produce halogen when heated. Mainly used in confined installations. |

The National Electrical Code (NEC) has a classification system for optical fiber cables. These requirements specify how the fiber cables will behave in case of fire conditions and categorize depending on its application for these different areas.

What is the Plenum Area?

A plenum area is a space used to move air to workspaces for the purpose of ventilation or to form air flow for an air distribution system.

What is the Riser Area?

Examples of riser areas are floor openings, tubes, or channels that run upwards over one or more floors. Riser cable is planned for use in upright shafts that run between floors.

What is the General-Purpose Area?

A general-purpose area is all other areas that are not plenum or riser on the same space or floor.

Fire Rating Levels

There are four levels of fire resistance for fiber cables and each level has two divisions which are the conductive and non-conductive cables. The higher rating cable is backward compatible to the lower rating cable and can be substituted while the lower rating cables can’t be used in place for the higher ratings.

OFNP and OFCP Fiber Cable

Optical Fiber Nonconductive Plenum Cable and Optical Fiber Conductive Plenum Cable. OFNP and OFCP cables as the name implies are used for plenum areas and have resistance to fire and smoke.

OFNR and OFCR Fiber Cable

Optical Fiber Nonconductive Riser Cables and Optical Fiber Conductive Riser Cables are used for the riser areas. These cables must prevent the fire from one floor to another.

OFNG and OFCG Fiber Cable

Cable Optical Fiber Nonconductive General-Purpose Cable and Optical Fiber Conductive General-Purpose Cable. These cables must not spread the fire for more than 4 feet, 11 inches.

OFN and OFC Fiber Cable

Optical Fiber Nonconductive and Optical Fiber Conductive. To get this cable rating, the flame shall not infiltrate floors or ceilings and the cables are also used for general purpose areas.

Comparison between the OFNR and LSZH Cables

Now we understand the different types of cable materials and their fire ratings, we can now clear the misconception between the OFNR and LSZH cables. These two cables are not the same type with just a different term. Failure to properly understand these classifications may lead to unfortunate accidents.

OFNR Cables

To summarize, OFNR cables are used for riser applications. It is non-conductive and is resistant to oxidation and degradation. It cannot be used to plenum areas but OFNP cables are compatible to rise applications. If you want to use it in a building, the structure must have a confined ventilation system and fire exits.

LSZH Cables

LSZH in comparison are made of special flame-resistant coating, and outstanding fire protection features such as low smoke, toxicity corrosion. LSZH cable jacketing are made of thermoplastic or thermoset compounds that produce little smoke and no halogen in case of fire.

When looking for the best type of fiber cable to use for your network and business, it can be difficult to navigate all of this information. We designed our premium fiber cables to take the guesswork out of it. Our premium fiber cables have the LSZH jacket material with the OFNR rating, which gives you the safety you need with the low smoke and toxicity, plus enables you to use the cable in riser-rated environments.