Drop cable, as an important part of FTTH network, forms the final external link between the subscriber and the feeder cable. Choosing the right FTTH drop cable termination or interconnect solution will directly affect network reliability, operational flexibility and the economics of FTTH deployment. So between the two FTTH drop cable termination methods: splice vs connector, which should you choose? What are the pros and cons of each termination method?

What Is FTTH Drop Cable?

FTTH drop cables, as previously mentioned, are located on the subscriber end to connect the terminal of a distribution cable to a subscriber’s premises. They are typically small diameter, low fiber count cables with limited unsupported span lengths, which can be installed aerially, underground or buried. As it is used in outdoor, drop cable shall have a minimum pull strength of 1335 Newtons according to the industry standard. Fiber optic drop cables are available in many different types. The three most commonly used fiber drop cables include flat drop cable, figure-8 aerial drop cable and round drop cable.

Flat Type Drop Cable

Flat drop cable, with a flat out-looking, usually consists of a polyethylene jacket, several fibers and two dielectric strength members to give high crush resistance. Fiber drop cable usually contains one or two fibers, however, drop cables with fiber counts up to 12 or more are also available now. The following picture shows the cross section of a flat drop cable with 2 fibers.

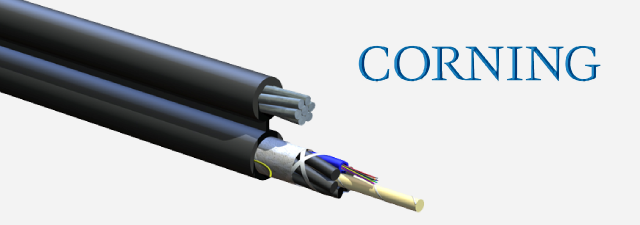

Figure-8 Aerial Drop Cable

Figure-8 aerial drop cable is self-supporting cable, with the cable fixed to a steel wire, designed for easy and economical aerial installation for outdoor applications. This type of fiber drop cable is fixed to a steel wire as showed in the following picture. Typical fiber counts of figure-8 drop cable are 2 to 48. Tensile load is typically 6000 Newtons.

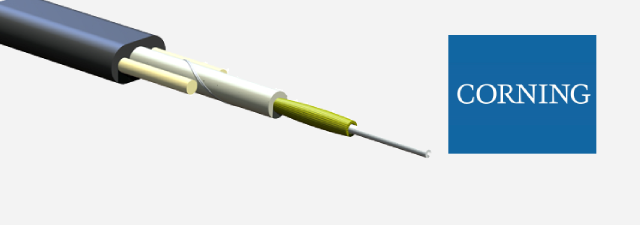

Round Drop Cable

Round drop cable usually contains a single bend-insensitive fiber buffered and surrounded by dielectric strength members and an outer jacket, which can provide durability and reliability in the drop segment of the network. The following shows the cross section of a round drop cable with one tight buffered optical fiber.

FTTH Drop Cable Termination Method: Splice or Connector?

It’s necessary to choose a right fiber optic cable for FTTH network from overall. However, FTTH drop cable as the final connection from the fiber optic network to customer premises also plays an important role. Thus, finding a flexible, efficient and economical FTTH drop cable termination method becomes a crucial part of broadband service. As mentioned in the beginning, there are two FTTH drop cable termination methods: splice and connector. Simply speaking, splice refers to permanent joint by splicer, while connector method can be easily mated and un-mated by hand.

Splice vs Connector: Each Has Its Pros and Cons

It is known that splice, which eliminates the possibility of the interconnection point becoming damaged or dirty with a permanent joint, has better optical performance than fiber optic connector.

However, splice lacks of operational flexibility compared with fiber optic connector. Fiber optic connector can provide an access point for networking testing which cannot be provided by splicing. Both methods have their own pros and cons.

Generally, splice is recommended for FTTH drop cables in the places where no future fiber rearrangement is necessary, like a greenfield, new construction application where the service provider can easily install all of the drop cables. Fiber optic connector is appropriate for applications which flexibility is required, like ONTs which have a connector interface.

Choosing the Right Splice Method

For FTTH drop cable splice, there are two methods. One is fusion splicing, and the other is mechanical splicing. Fusion splice has been proved to provide a high quality splice with low insertion loss and reflection. However, the initial capital expenditures, maintenance costs and slow installation speed of fusion splicing hinder its status as the preferred solution in many cases. Mechanical splicing is widely used in FTTH drop cable installation in countries, as a mechanical splice can be finished in the field by hand using simple hand tools and cheap mechanical splicer (shown in the following picture) within 2 minutes.

Choosing the Right Connector

For fiber optic connector, there are two types of connectors for FTTH drop cable connection. Field terminated connector, which contains fuse-on connector and mechanical connector, and pre-terminated drop cable, which is factory terminated with connector on the end of drop cable.

Fuse-on connector uses the same technology as fusion splicing to provide the high optical connection performance. However, it requires expensive equipment and highly trained technician, and more time like fusion splicing. Mechanical connector could be a replacement of fuse-on connector (shown in the following picture), if the conditions do not fit the mentioned ones. It could be a time-save and cost-save solution for drop cable termination.

Choosing the Right Connector

For fiber optic connector, there are two types of connectors for FTTH drop cable connection. Field terminated connector, which contains fuse-on connector and mechanical connector, and pre-terminated drop cable, which is factory terminated with connector on the end of drop cable.

If you have no limits in cost and want high performance termination in a time-save way, pre-terminated drop cable could be your choice. Many factories can provide you customized drop cables in various fiber types, fiber optic connector and lengths.

Conclusion

Customer demand for higher bandwidth will continue to drive the development of FTTH as well as its key component like FTTH drop cable. Choosing the right FTTH drop cable and fiber optic drop cable termination method is as important as choosing the right network architecture in FTTH.